Out of 165 letters of intent and 56 full proposals, the Anschutz Acceleration Initiative (AAI) named nine final awardees to receive a portion of the $50 million commitment from The Anschutz Foundation. Among the top recipients was Jeffrey Stansbury, PhD, senior associate dean for research and professor in the Department of Craniofacial Biology at the University of Colorado School of Dental Medicine (CU SDM).

Stansbury and his multidisciplinary team are at the forefront of dental research, particularly focused on transforming denture care with new bioactive materials.

“This is the biggest grant that I’ve ever received both in terms of the dollar amount and the complexity of the internal and external partnerships that will be necessary to make it a success,” Stansbury said. “It’s nice to get a grand slam like this to further our research and make an impact.”

Stansbury credits his team for helping him accomplish these significant research achievements. Team members include:

- Sangeetha Chandrasekaran, BDS, MS, MS, Professor and Chair, Division of Periodontics, Diagnostic Sciences and Surgical Dentistry;

- Bruce Dye, DDS, MPH, Professor and Chair, Department of Community Dentistry and Population Health

- David Gozalo, DDS, MS, Associate Professor, Restorative Dentistry;

- Nicholas Jacobson, MDes, School of Engineering Design & Computation, Inworks;

- Devatha Nair, PhD, Associate Professor, Craniofacial Biology;

- Chaitanya Puranik, BDS, MS, M.Dent.Sci., Ph.D Diplomate, Associate Professor, Children’s Hospital Colorado and School of Dental Medicine; and

- Michael Schurr, PhD, Associate Professor, Immunology and Microbiology.

Fueled by the AAI grant, the team’s initiative is to help bridge the gap between adults in poverty and economically advantaged adults who use or may need dentures.

Novel technologies promise affordable, quality dentures

The core of the research lies in the integration and further exploration of two novel dental technologies developed independently on the CU Anschutz Medical Campus.

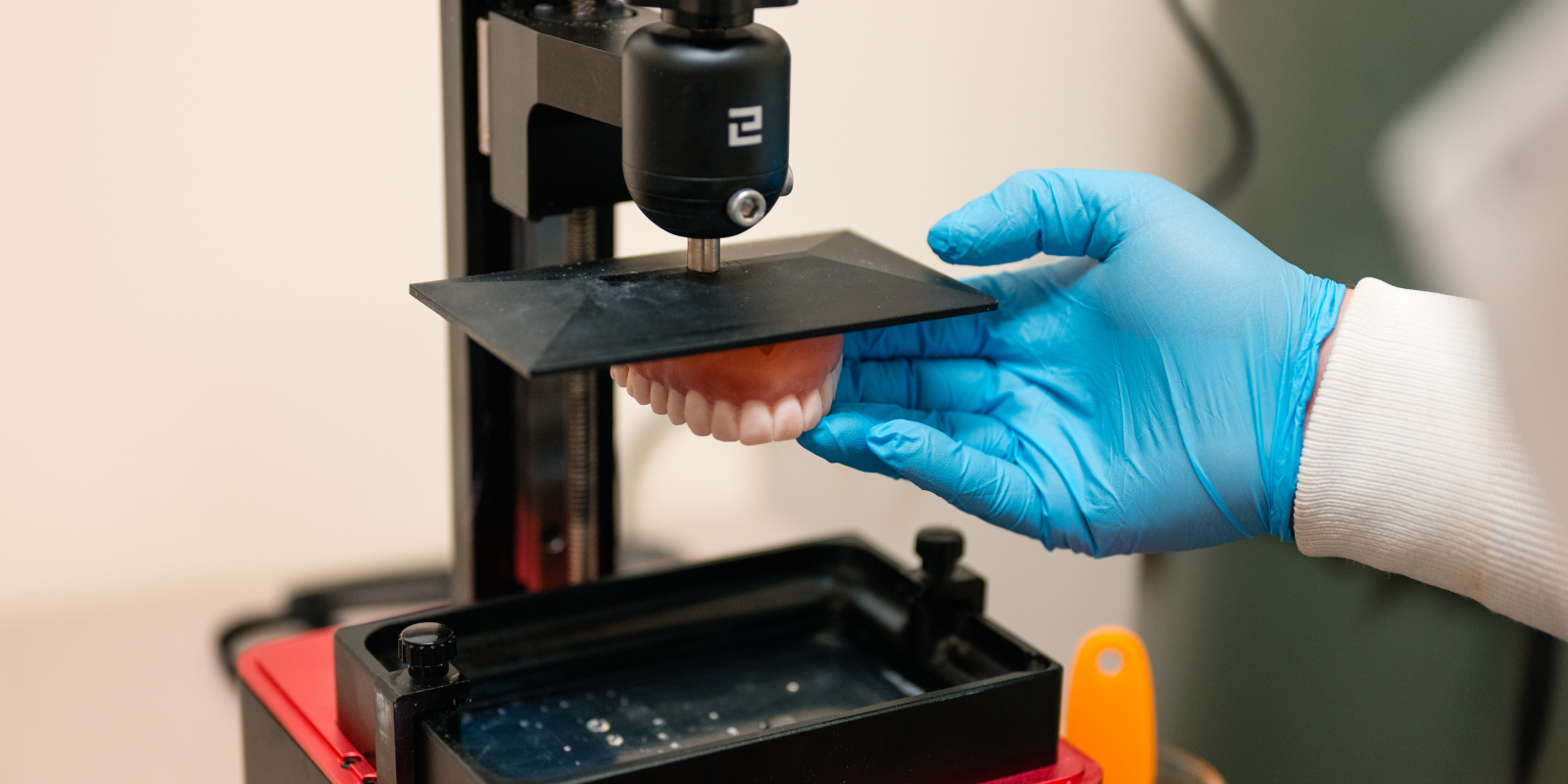

The first is the development of unusually strong, tough and wear-resistant photopolymers that are uniquely suited for 3D inkjet printing. This means a high-performance denture can be rapidly completed in a very efficient, single-step process, rather than printing each material separately and attaching them later.

Jeffrey Stansbury, PhD, and his expert team have been able to inkjet print very esthetic, high-performance dentures. The AAI grant will allow the team to advance their work even further. |

“We’re upping the performance of the denture teeth and the denture base with multi-material printing,” Stansbury said. “For example, instead of printing a hard tooth and a semi-flexible base, now we can print customized transition zones where the material goes from harder to softer with a graded interface in one piece.”

Not only does this help with the stability and longevity of the denture material, but it also offers greater precision and customization of the denture to fit individual patient needs.

The second technology involves photocurable polymers that selectively eliminate streptococcus mutans bacteria, commonly known as strep. The risk of things like strep and biofilm formation is a common problem with all dentures, but especially for patients who are less compliant with their oral healthcare.

Stansbury said, “These materials have a kind of wound-healing character to them. If there’s a lesion in the mouth, they may enhance the healing process. And because they effectively get rid of strep, which is a precursor to a lot of biofilms and other issues we see intraorally, they will also help alleviate those problems.”

Combining these two approaches promises esthetic, premium-quality dentures with antimicrobial and potentially antifungal characteristics that can improve patients’ oral health along with the function and appearance of their dentures.

Stansbury and his team’s work will ultimately lead to the development of a series of dental products, promising enhanced affordability and improved clinical value for patients with limited access to care.

“We have a very clear path to moving this to actual clinical application,” Stansbury noted. “Both Dr. Nair and I have formed small companies from our individual research, so we can take advantage of the fact that we are already well down that pathway to clinical engagement.” Much of the legwork that goes into launching a new product like this, from licensing to acquiring patents and developing partnerships, is already complete.

Accelerated research leads to healthcare innovation

After years of research and many iterations to get to this point, Stansbury’s company is ready to produce first-generation 3D inkjet-printed dentures in early 2024, using the high-performance jettable inks they’ve created that can accommodate these novel materials. They have been working with Myerson dental manufacturing company to develop a new 3D inkjet printer, which will be launched alongside the jettable inks at the Chicago Dental Society Midwinter Meeting in February.

Thanks to the AAI grant funding, the combined research team expects to produce subsequent versions of these dental materials that will have even higher mechanical properties, varied material compositions in the denture base and the teeth, as well as the antimicrobial aspect.

Dental laboratories will be able to use this breakthrough printing process to make fixed or removable complete dentures in considerably less time, with better quality materials and top-notch performance.

“The time and cost savings this will offer is incredible,” said Stansbury. “What used to take days or even weeks for labs to make will now be done in a matter of hours. Technicians won’t need to do any additional processing to make multiple pieces fit. The proposed 3D inkjet-printed teeth are expected to have properties approaching that of some dental ceramics, and well beyond what is available with current polymer-based materials.”

The CU SDM will be the first dental school to have this capability, with an in-house inkjet printer dedicated for clinical use, exclusively for CU Dental patients. Faculty, students and residents will learn to use this technology through the school’s digital dentistry program, led by Associate Professor David Gozalo, DDS, MS.

CU SDM Dean Denise Kassebaum, DDS, MS, expressed her enthusiasm, stating, "This initiative exemplifies our commitment to advancing dental research and improving patient care. The collaboration between these esteemed researchers showcases the dedication of the dental school and greater campus community to making a real difference in oral health care.”

As part of the recent AAI award, the SDM proposes to establish a pathway for Veterans, seniors and patients with special healthcare needs to participate in clinical trials that examine how these new oral appliances can improve health and quality of life.

With a focus on affordability, clinical value and cutting-edge technologies, Stansbury and team stand on the precipice of reshaping denture care. The AAI grant not only propels their research forward but also underscores the commitment to patient-centric dentistry and healthcare innovations at the CU School of Dental Medicine.