Editor’s note: “Our COVID-19 Fighters” is an occasional series highlighting the ways the CU Anschutz Medical Campus community is helping patients and the wider community in the fight against the pandemic. We welcome your story ideas; please share them here.

In March 2020, when COVID-19 lockdowns took the lab away from two creative minds in the University of Colorado School of Dental Medicine (SDM), the researchers within them refused to sit idly by and watch the pandemic unfold.

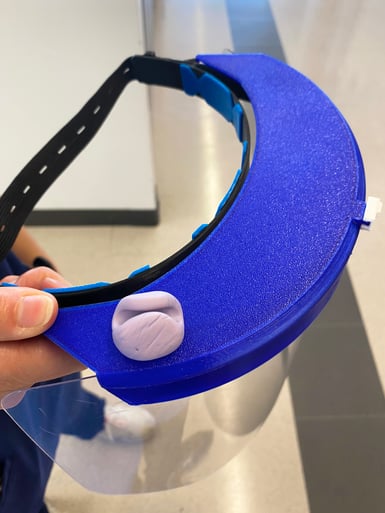

Alfred Li, a third-year dental student, emailed his mentor, Thomas Greany, DDS, for ideas on designing a face shield. His intention: Customize a shield for their profession that would help keep their colleagues safe and prevent a shortage of personal protective equipment (PPE) from stalling their return to work.

Today, with the CU Anschutz Medical Campus gearing up for a fuller return to campus, Li’s peers stand ready with a revolutionary face shield that represents the caliber of multi-disciplinary innovation that takes place on the region’s top medical campus. It also saved the school a chunk of money, paring the cost of face shields it had been using from $5 each down to 17 cents per unit.

Pinpointing a problem

“It’s nice to identify a problem and solve an issue that’s really relevant to what’s happening in the world and especially in our profession,” Li said. “And even with all these different things that were going on (restrictions, lockdowns, fears of infection) we were still able to collaborate inter-professionally because of technology.”

With the open-source spirit spurred by the world pandemic, Greany, whom Li described as “like-minded” in his passion for solving problems, quickly found a 3D-printed face shield by Prusa Research. After surveying faculty and students for information on equipment they used, the pair realized the Prusa design didn’t meet their colleagues’ needs.

Magnifying loupes and headlamps for peering into patients’ mouths are crucial for performing intricate dental procedures, and the Prusa design would require lamp attachment inside the shield.

“So, they’d have to stick their gloved hands that had just been in someone’s mouth up under their face shield to manipulate their light,” Greany said. “That’s not good.”

Recruiting a team

Enlisting the help of Inworks, the university’s innovation initiative, the pair turned into a trio, joined by Inworks design engineer Hayden McClain. “One of the core tenets of our group is this idea of human-centered design and really diving into the needs of creating something that will be functional,” McClain said of Inworks, which has labs on the CU Anschutz and CU Denver campuses. “This project just fell right into our process.”

Using Inworks’ creative staff and top-of-the-line 3D technology, McClain implemented modifications allowing headlamp mounting outside the shield and space for magnifying loupes inside the shield and created a prototype.

Li and Greany, an SDM clinical assistant professor, then recruited a group of 60 dental students to test the prototype and provide feedback. “Some people would say: ‘Oh, my head’s too small,’ or ‘I think there should be another strap on it that goes right down the middle of your head to keep it from slipping,’ Greany said, adding that he was impressed with the students’ ingenuity and enthusiasm.

After realizing the plastic head strap was leaving a footprint on their heads after four hours of clinical work, one student suggested using a cushioning commonly used for wrapping dental X-ray components before inserting them in patients’ mouths, to soften the inside of the straps.

Cutting cost and waste

“It was just cool,” Greany said. “Everybody kind of stepped up and said: ‘Hey, we should try this.’ And the best part of it all is, we were spending literally $40,000 in October on face shields,” Greany said. “This cut that down to a fraction of the cost. So, it was a nice kind of homegrown solution.”

Inworks used an eco-friendly design that provided more flexibility with the shields. “You can swap out parts and increase the longevity,” said McClain, whose team bumped the shields from one-time use to as many as 30 or 50 uses. “Originally, the dental team asked for about 500 shields to start, but that was in the mindset of these disposable, single-use shields.”

Inworks used an eco-friendly design that provided more flexibility with the shields. “You can swap out parts and increase the longevity,” said McClain, whose team bumped the shields from one-time use to as many as 30 or 50 uses. “Originally, the dental team asked for about 500 shields to start, but that was in the mindset of these disposable, single-use shields.”

With the exchangeable parts, the school ended up needing fewer shields. “You can change parts as they break and reduce your waste and reduce your spending per unit,” McClain said. “That was the goal. And it worked out really well.”

McClain, who is in the process of open-sourcing the design for other dental schools to use, said the project required a lot of iteration, with frequent “back-alley” swaps of designs and prototypes because of COVID restrictions and plenty of Zoom work sessions.

Collaborating for the future

The project also represents the importance of collaboration between design engineers and clinicians, he said. “I think it was exciting for both sides. We have a lot of skills that complement each other and, when put together, can create some really amazing projects. We created something of high value that is actually being used and will be used for quite a while.”

Li has received feedback from peers that they intend to use the shields for certain procedures post-COVID.

With his eye on a career in orthodontics, Li said the project will also propel him into the technology-heavy field. “My goals are to keep going with these innovative engineering projects and hopefully change dentistry by creating new things that we can use for diagnosis and treatment.”

Inspiring innovation and providing the technology needed for the future is crucial for medical schools, said Li, adding that he’s thankful for the 3D resources Inworks and CU Anschutz provide. “In my mind, it is the future of dentistry, and there are new products coming out every day to support that.”